If you’re involved in marketing, design, or any other banding-oriented role, you have probably been faced with the confusing decision on if you want your marketing items printed on an offset press or digital printer. What does this mean? How are you supposed to know? Well, join us for a deep dive on what offset printing is. Understanding the process helps to understand how files need to be set up and why.

the basics

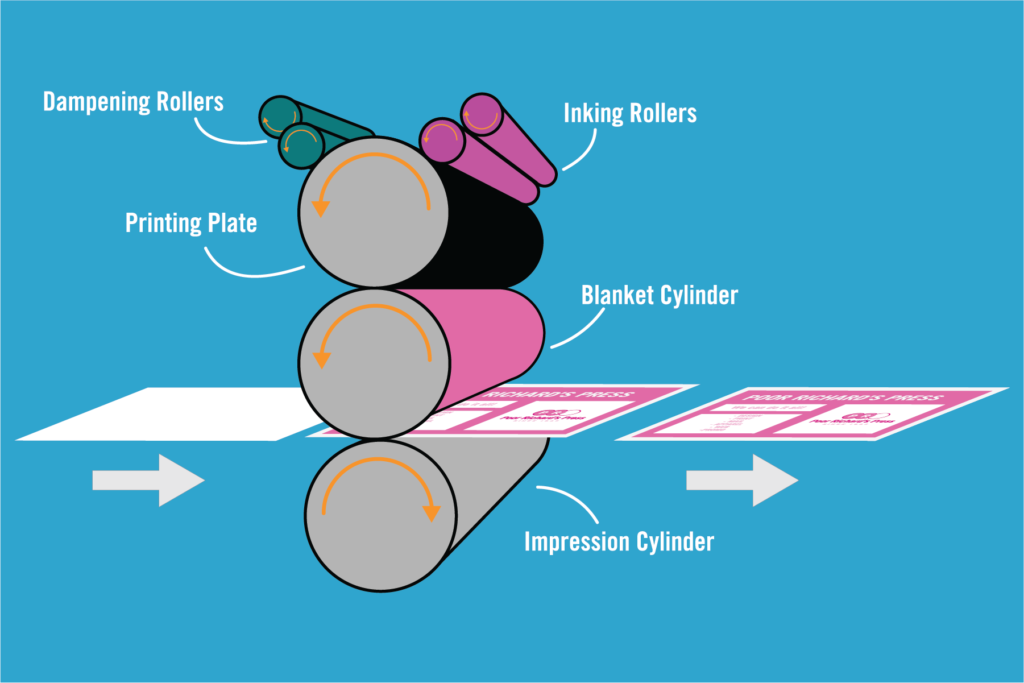

Summed into a few sentences, offset printing is a technique that transfers ink from a plate (usually made of aluminum) onto a rubber roller or blanket. From this roller or blanket, the ink gets transferred onto various substrates to produce high quality designs and images. Offset printing is commonly used for mass production and high-quality print items.

prepress

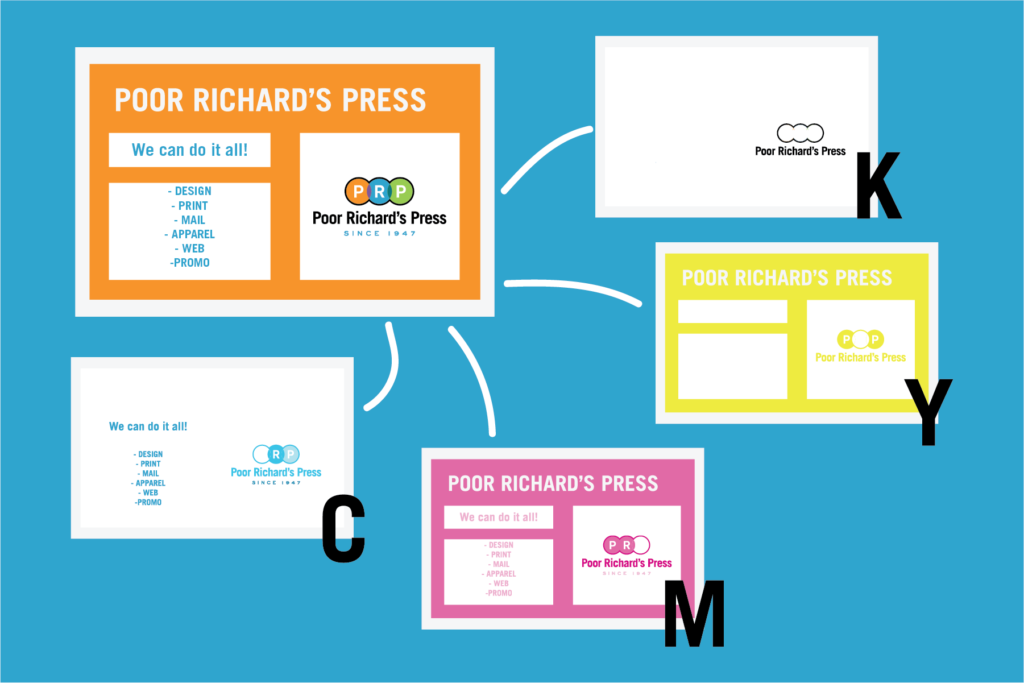

Before anything can be printed, the print files must be adjusted to work for the offset press. One of the most important parts of this process is converting the file into CMYK (Cyan, Magenta, Yellow, and BlacK) color profiles. CMYK is important because the file will have one plate per primary color. These four colors can then combine to create a full rainbow of colors.

The prepress team converts the PDF files into files that the plate maker can read. From there, the plate maker makes four plates, one for each CMYK color. There can also just be one plate produced if it is a black and white file, or more then four plates if there are additional coatings (for example, pantone colors). From there, the plates move onto the printer for the next process.

Printing process

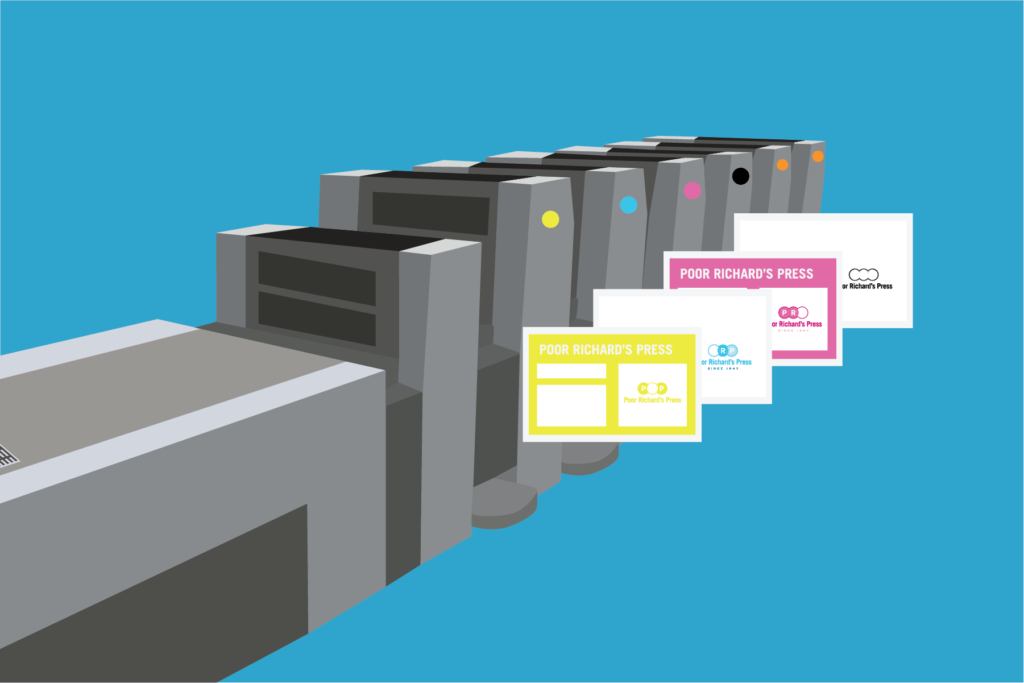

The printing process starts with the press operator inserting the plates onto the rollers. Each plate gets inserted into the corresponding section of the press (each printing company can have their color order set up in different orders). For example, the cyan plate gets put in the designated cyan section of the press, same with magenta, etc. If there are extra plates for other inks such as pantone inks, metallic inks, or coatings, these also get put into the extra color sections (labeled with orange circles in the diagram above).

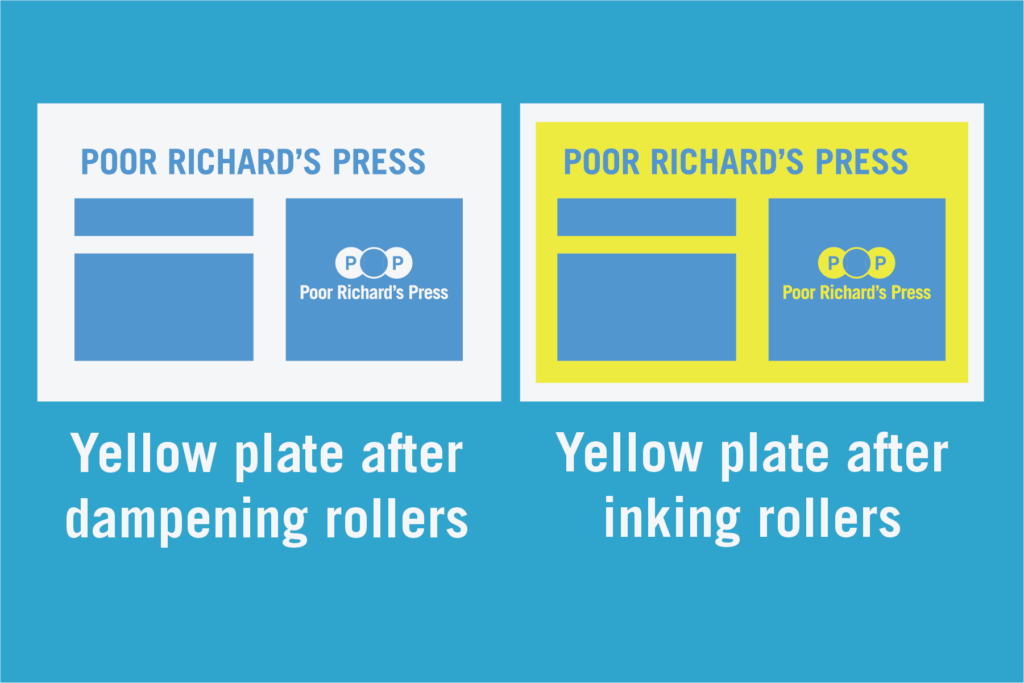

The printing process begins with individual sheets being pulled through the machine. As the sheets travel through each color section the following process happens. The printing plate cylinder (where the aluminum plate is wrapped) turns and first meets with the dampening rollers, here water fills the area of the plate where no ink is wanted. Next, the printing plate meets the inking roller, this is where the ink is applied to the plate to create the desired image.

After, the printing plate rolls the inked image onto the blanket cylinder (a rubber lined cylinder). It is the blanket cylinder that actually puts the image onto the sheets of paper. Pushing against the blanket cylinder and pressing the ink into the page is the impression cylinder.

The sheets of paper then follow the same process for each color, finally creating a full color page. Before the pages are stacked on top of each other, a thin layer of dust is applied to the top and bottom of each page as to avoid pages getting ruined from touching while drying.

Benefits of offset printing

- High quality

Offset presses are able to achieve high quality and clear images. Because offset presses use ink instead of toner, richer colors are able to be achieved. - Low Cost

When running a medium or high quantity job, offset printing can be very economical. The more quantity being printed, the lower the cost per unit. - Fast Turnaround Times

For large print projects, offset is the way to go. Offset presses don’t need to be stopped in the middle of a run to replenish ink or add more paper. This allows for big jobs to get done faster.

We hope this overview provides a solid understanding of how an offset press works. If you want to start a new print project with us or have any questions contact us here.