With all of the various options and styles of print binding out in the world, it’s easy to get lost on the path to finding what binding method best suits your project. We hope to help simplify your path to decision-making by providing a guide on the most common binding methods for small business and commercial needs. In this blog we will show you the main differences between the most frequently used binding methods and their purposes.

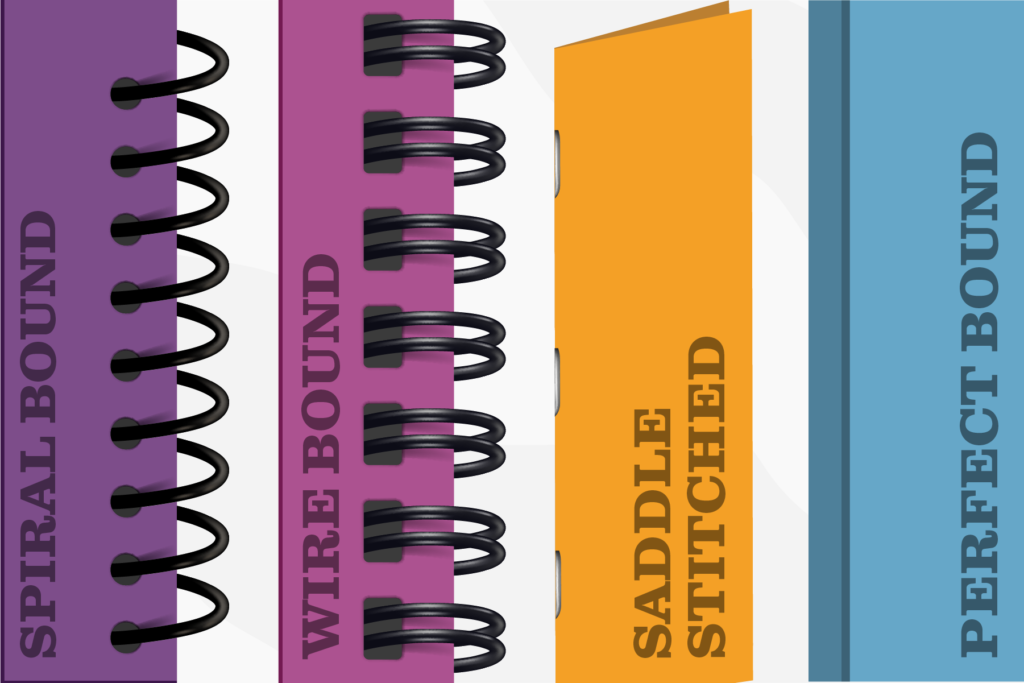

SPIRAL BINDING

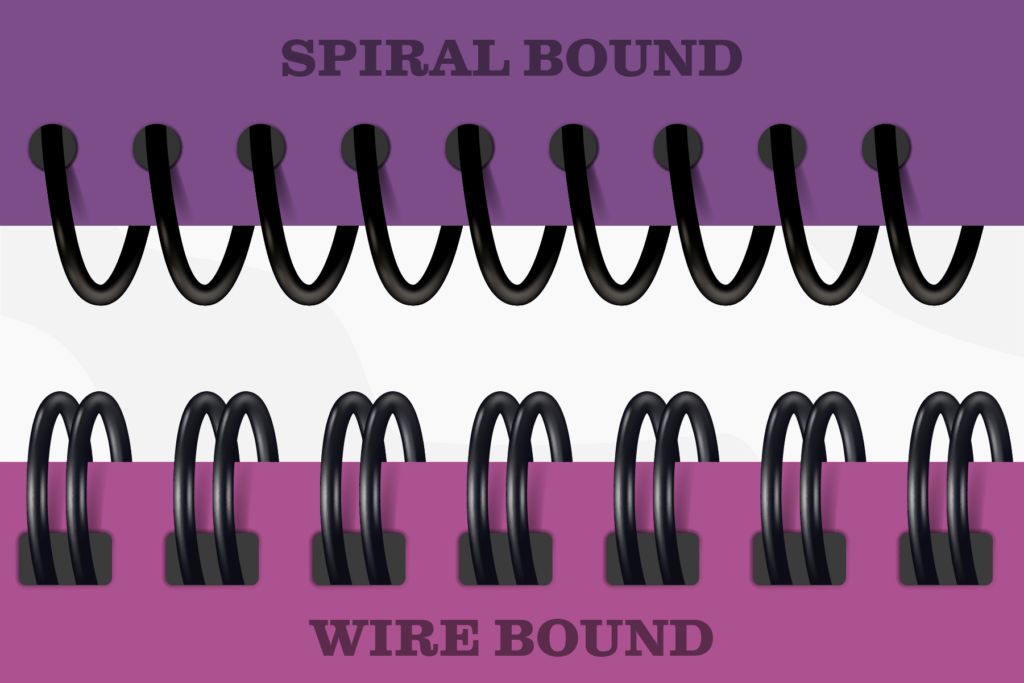

One of the most commonly used and recognized bindery methods, Spiral Binding. With the ability to lay flat when open, spiral bound books are a popular choice to be paired with a sturdy cover sheet for internal reference books, workbooks filled with interactive worksheets, notebooks, and calendars. With coil sizes small enough for 10 sheets to large enough for 500 sheets, spiral binding fits the diverse printing needs of all industries. Also referred to as “Coil Binding” this method is extremely durable and withstands heavy use. When produced, evenly spaced round holes are drilled into the printed books. Then the PVC coils are fed through each hole of each book (with the assistance of equipment to speed it up!) and clipped at each end to secure the coil. For a sturdy, long lasting hold, consider spiral binding!

WIRE BINDING

While this method looks extremely similar to spiral binding in finished results, Wire Binding is slightly different. Also referred to as “Wire-O” binding, wire binding uses wire as opposed to PVC coils. From a glance, the biggest difference appears to be the appearance of the coil. However, the process strongly differs from spiral binding as instead of feeding the coil through the holes, a different piece of equipment is used to hold and crimp the wire to form the bind. Wire binding is often chosen to bind smaller, more delicate, and presentation documents, as it performs best with a lower page count. The largest downside to the wire binding method is the fragility of metal and its tendency to hold bends. Wire binding still provides the ability for the document to lay flat when open.

AN UP CLOSE GLANCE – Lay CoMPLETELY flat when open

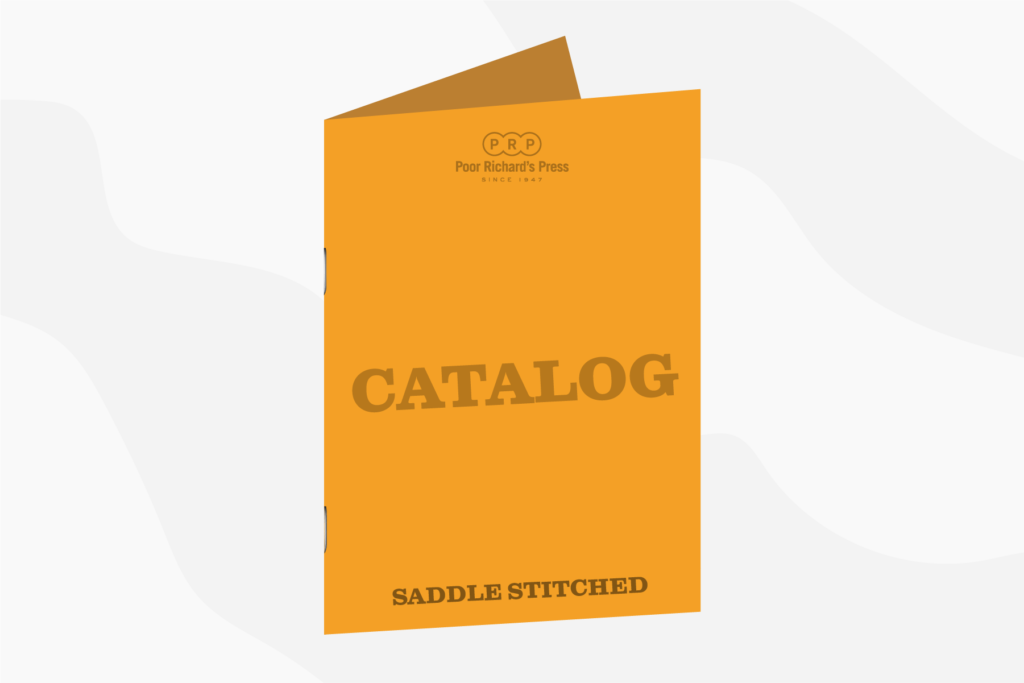

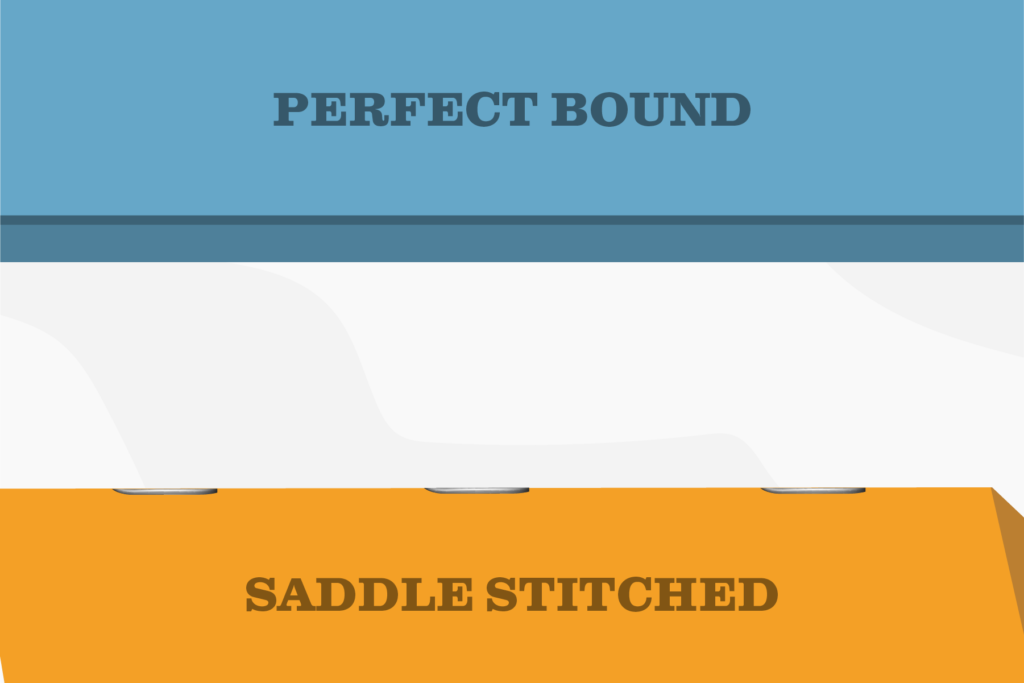

SADDLE STITCH

Saddle Stitching is one of the most commonly chosen binding methods for catalogs, brochures, and booklets. For this process, the printed piece gets sent through the machinery as if it’s sitting on a saddle, with it open face-down and split down the middle. Then, two staples are put in the spine of the book to hold each page together for a beautiful finished piece. Two staples are the standard, however more can be used to accommodate larger pages and booklets. While it won’t lay as flat as the aforementioned methods of bindery, saddle stitched books are your typical magazine bind and typically won’t close themselves as they remain lightweight. Saddle stitching is efficient in production and remains one of the most popular, cost-effective binding options.

PERFECT BINDING

Perfect Binding is a method used most commonly on books and catalogs. Perfect Binding differs from the previously discussed methods as it uses adhesive to hold the pages together when produced. Books created this way have a perfectly bound rectangular backbone (spine). A caveat to this method is the lack of ability for the book to lay flat when open. Due to the adhesive and labor, this method also tends to result in a higher cost and longer turnaround time than the others mentioned in this overview.

AN UP CLOSE GLANCE – NoT COMPLETELY FLAT WHEN OPEN

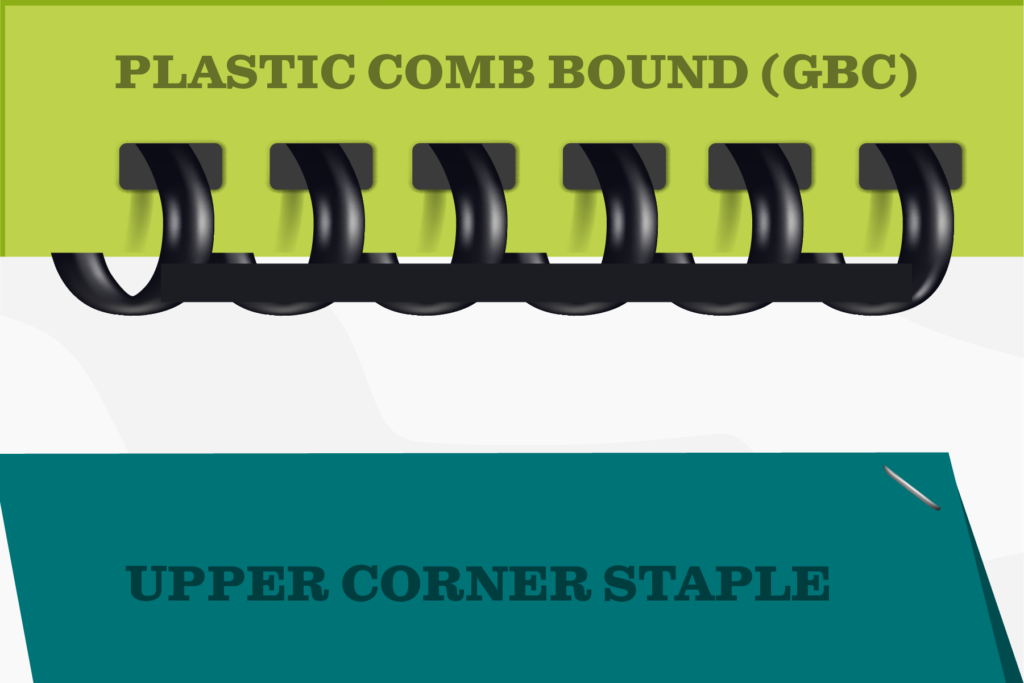

PLASTIC COMB BINDING (GBC) & UPPER CORNER STAPLE

These last two methods may be less frequently chosen, however they still serve their diligent purpose as binding methods!

Plastic Comb Binding (or GBC) is another lay flat option utilizing thin plastic combs to hold the pages together. This method is common for informal documents and workbooks. An advantage to these plastic combs is the variety of colors available on the market.

Upper Corner Staple is another alternative method that can be applied in production on the copier machines. A single upper left corner staple is most commonly used for documents of smaller page count like rental agreements, onboarding forms, and medical packets. Since pages held together in the top corner will not lay perfectly flat on its own, this method may not fit every application.

TO CONCLUDE

The six methods explained above are great options for your next project needing to be bound. Be sure to consider the number of pages, size of sheets and the intended final use when deciding which method fits your needs. At Poor Richard’s Press, our experts are always ready to help you in finding the best fit for all of your print needs!